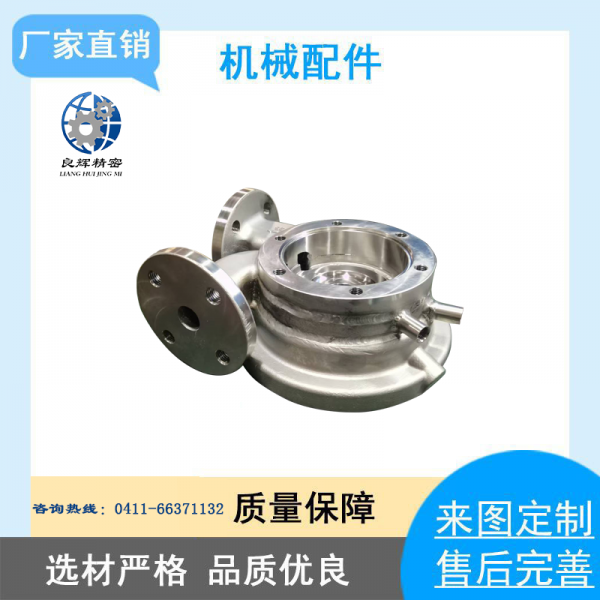

电解抛光工艺流程

,

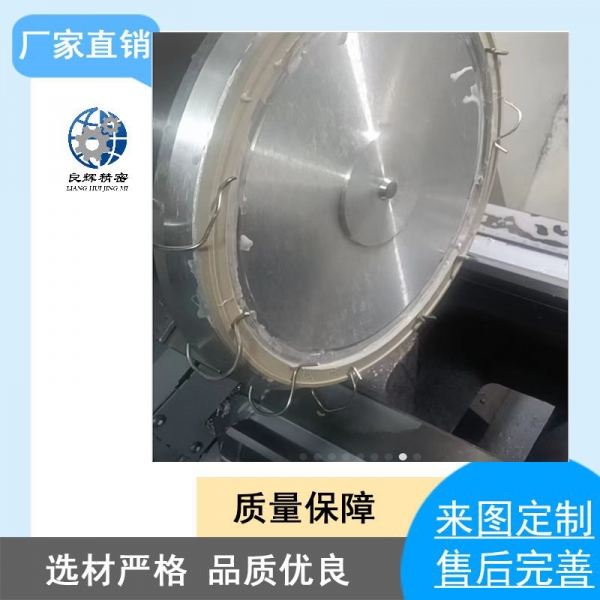

电解抛光是以被地工件为阳极,不溶性金屈为阴极,两极同时浸入到电解槽中,通以直流电而产生有选择性的阳极溶解,工件表面逐渐整平,从而达到工件增大表面光亮度的效果。

1、电流规格100A/200A/300A/500A/1000A/15004/2000/3000,/50004/7500A电压12伏或者15伏。也可以根据用户实际情况定制。

2、主机采用高频整流,含有时间、电流、电压、温控、播摆设定及数字显示,含有过热及短路保护装置。

3、本设备采用流水线设计方式,非常便于实际操作,大大提高生产效率。

4、设备配置酸洗槽、电解槽、清洗槽、钝化槽、消洗槽

5、曹体采用防腐12mm PP材料制作,符合环保要求。

6、提供全方位的技术服务,包括设备的调试及电解抛光技术培训。

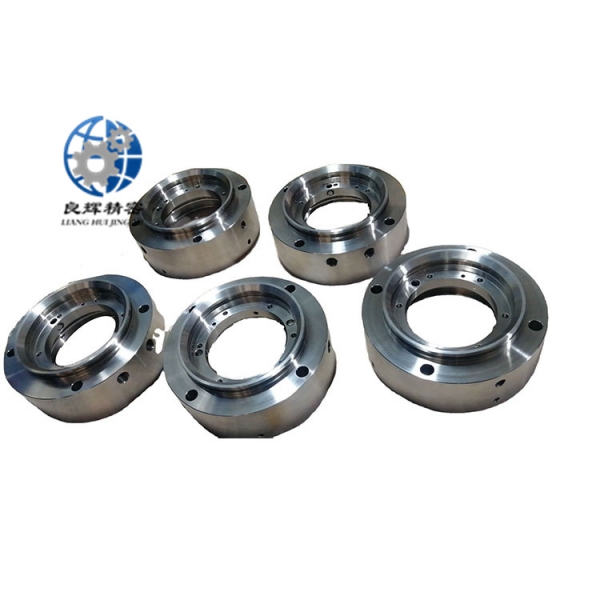

适用材质范围:

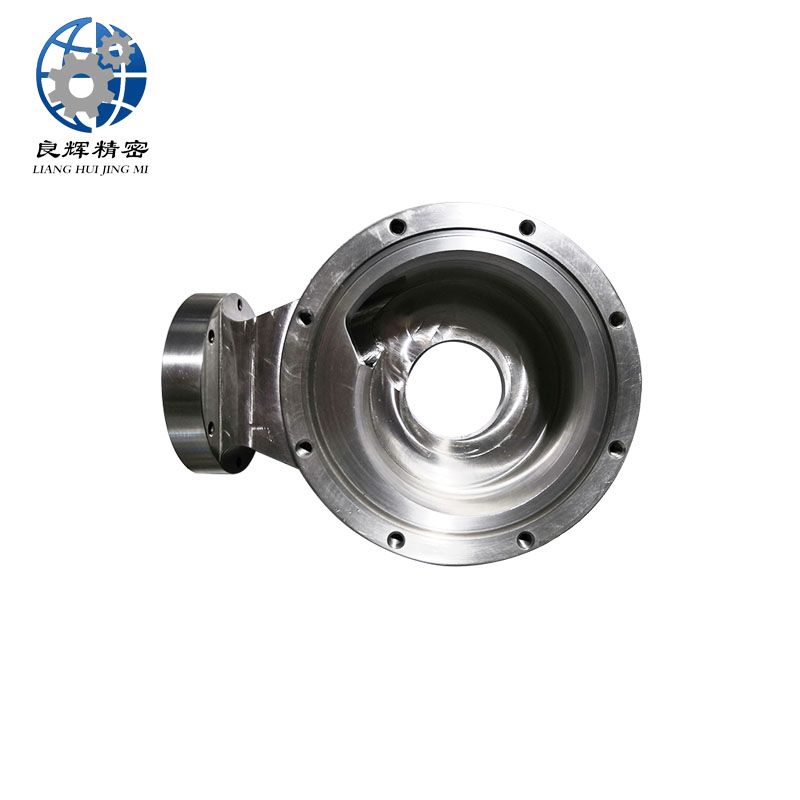

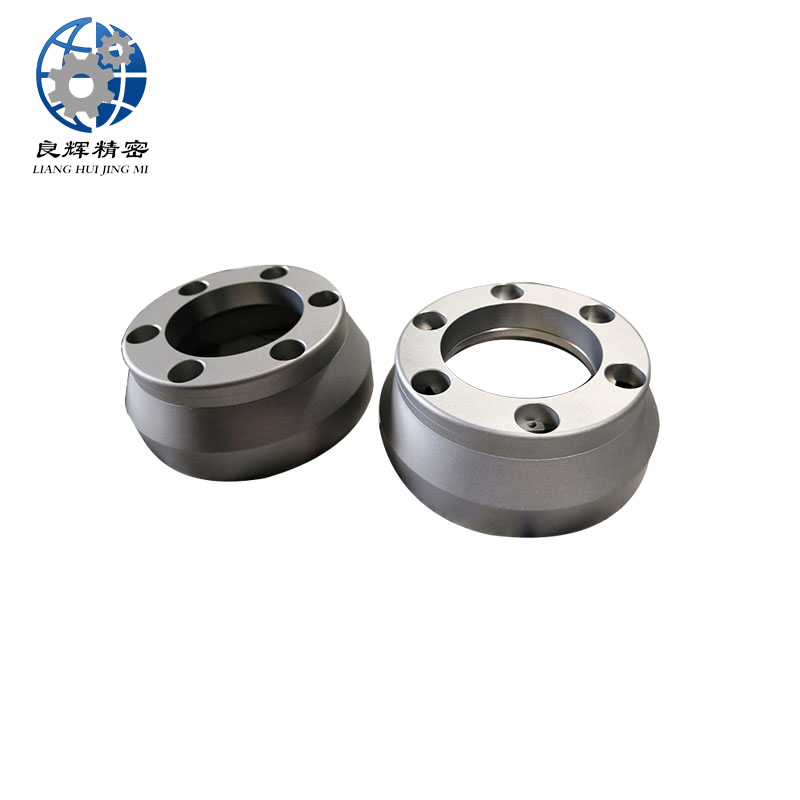

1、不锈钢(包括马氏休、奥氏体及铁素休)

2、铝及其合金

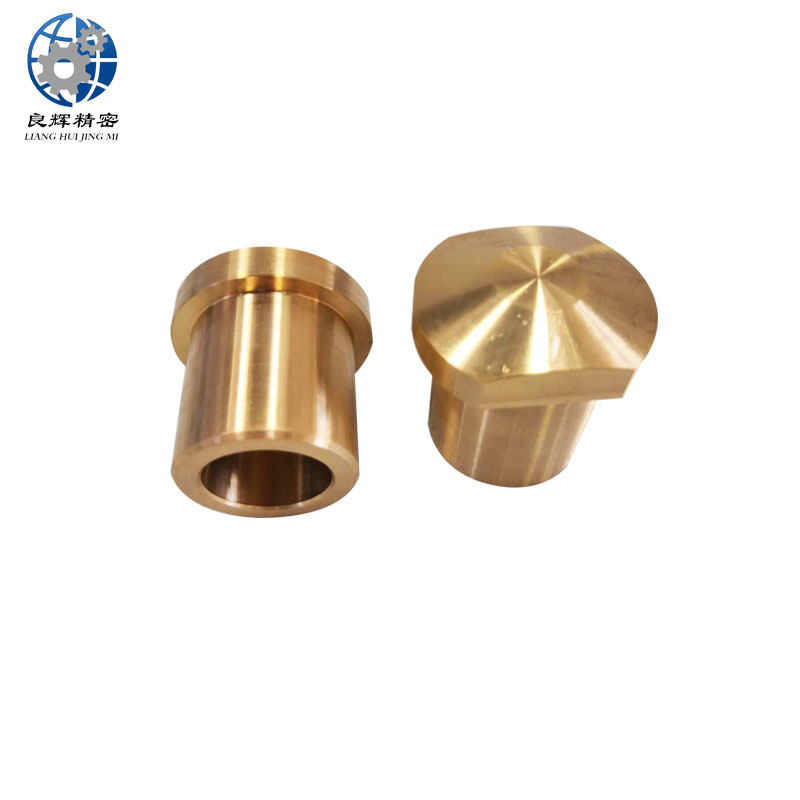

3、铜及其合金

4、钢铁件

一般组合包括:

整流机+抛光槽+阳极棒+阴极棒+阴极铅板+两级铜线+石英加热器+抛光液+电解挂具(添加时间控制仪+温控仪) 。

组装流程:1、两级电线:

1,整流机500A以上电线为4跳,分AB两种颜色, A颜色电线接整流机正极和抛光槽阳极棒(中间). B颜色电线接整流机负极和抛光槽阴极棒(两边)

2、阴极铅板:铅板应挂在阴极棒上 (两边)注意卡紧整齐。

3、石英加热器:放在曹体头上角的两

石英加热器电压: 220: 2KW和3kw.

石英加热器必须保证抛光液到位的情况下才可以加热使用,温度40-70。

Be careful:

1. Wave removing and degreasing refers to: if there are oil stains, rust evolution and other impurities on the stainless steel surface, it is recommended to thoroughly clean the surface with energy stainless steel cleaning agent, and then conduct electrolysis based polishing. Otherwise, the oil stain on the stainless steel surface will not only affect the surface after electrolytic fingering, but also affect the service life of stainless steel. Therefore, this process is necessary

2. Electrolysis refers to light: before the electrolysis of stainless steel parts, it is necessary to heat the stainless steel electrolysis hot light liquid heating car by 50-75 degrees, and stir the electrolysis 1 light liquid temperature well evenly to ensure that the sugar liquid temperature is the same, check and clamp it, the workpiece shall not have obvious varicella before the bath, and the current and voltage can be adjusted at any time according to the actual needs of the site and operation,

3. Soak and wash: This is the most easily neglected link after electrolysis. After the electro-luminescence, it is necessary to use flowing water to wash the surface of stainless steel pin first, and then use clean water to soak the stainless steel parts for three minutes, so as to fully recognize the electrolysis, and the light is removed and washed, so that you have about water left on the stainless steel parts of the car, resulting in only or fake bottom marks

4. Bake in the package; there is no special requirement, which can be determined according to the actual situation.